Robotic Systems Gallery

Robotic Arm Systems

A multi-axis robotic arm that mimics human motion with greater power and precision. Designed for confined or hazardous spaces where manual jetting isn't safe or effective. More flow, more coverage — without fatigue or risk.

Automated Concrete Removal Robots

Removes concrete with automated hydrodemolition robots with programmable nozzle positioning and adaptive path-following — engineered for material removal, not precision machining. No vibration. No rebar damage. No overcutting.

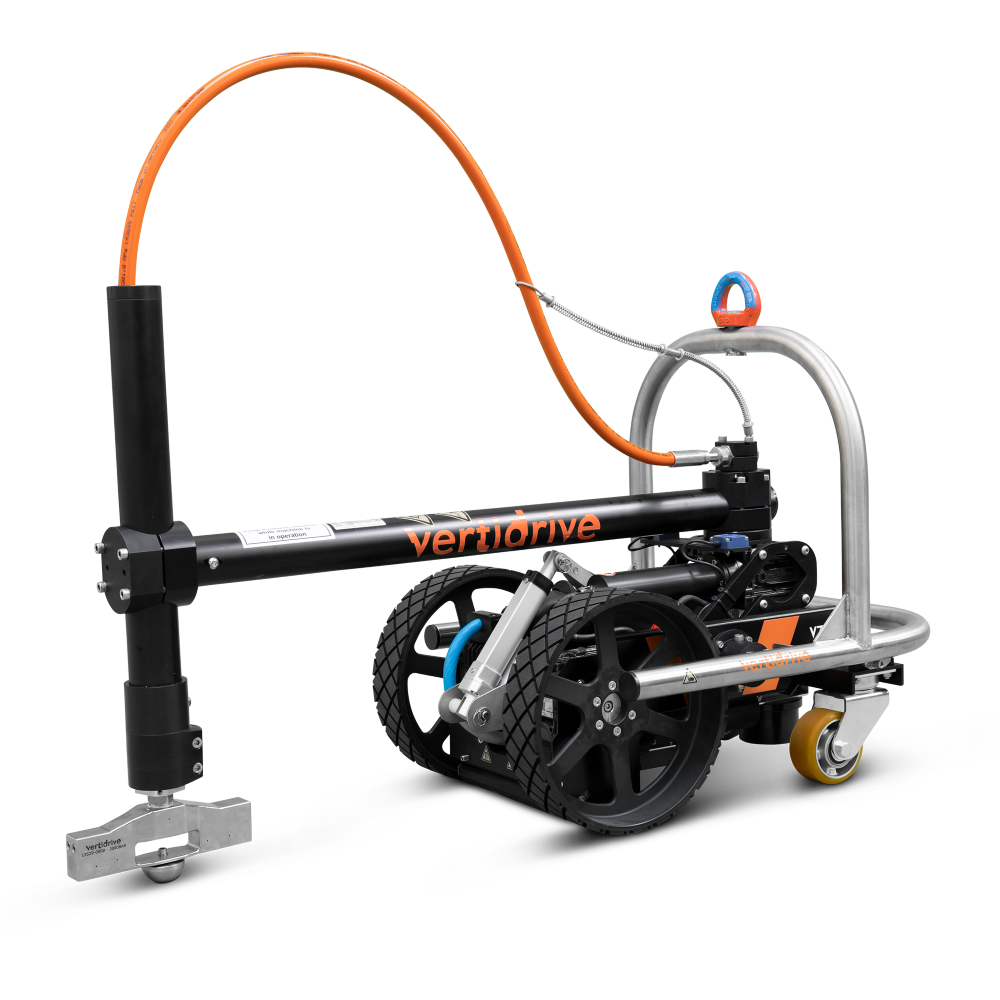

Magnetic Crawler Robots

Clings to vertical or overhead steel surfaces to remove scale, rust, and coatings at 30,000+ psi. Used for tanks, ship hulls, and large steel assets with zero manual risk.

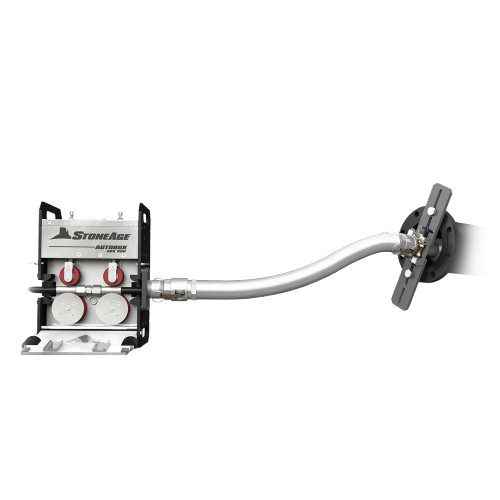

Automated Cleaning Systems

Automatically cleans the internal diameter of pipes, heat exchangers, and tanks or vessels. Consistent coverage. Faster flow or designed capacity restoration. No confined entry required.

Note on Control Systems:

While our robots use motion control, programmable automation, and precision pathing, they do not use CNC (Computer Numerical Control) in the traditional sense. These systems are optimized for material removal, cleaning, or coverage — not for machining or G-code-driven subtractive manufacturing.

Manual vs Robotic Comparison

| Factor | Manual | Robotic |

|---|---|---|

| Operator Fatigue | High | Zero |

| Precision | Varies | Surgical precision |

| Coverage Speed | Slower | Faster |

| Safety Risk | High | Remote operation |

| Repeatability | Low | High |

Our systems don't just remove risk — they deliver surgical-level precision every time.

Where Robots Excel

Tank Shell Blasting

Concrete Milling

Pipe Descaling

Overhead Cleaning

Hazardous Zone Work

Drain & Sewer Jetting

And more — if water can reach it, we can automate it