When to Automate: 3 Signs Your Operations Are Ready

In the rapidly evolving landscape of industrial operations, the question isn't if you should automate, but when. Timing is everything—automating too early can strain resources, while waiting too long can put you at a competitive disadvantage.

Sign #1: Repetitive Tasks Are Consuming Skilled Labor

When your most valuable team members spend more than 30% of their time on repetitive, low-value tasks, it's a clear indicator that automation could free them for more strategic work. This is especially true in maintenance and cleaning operations where specialized knowledge is being underutilized.

Sign #2: Quality Inconsistency Despite Best Efforts

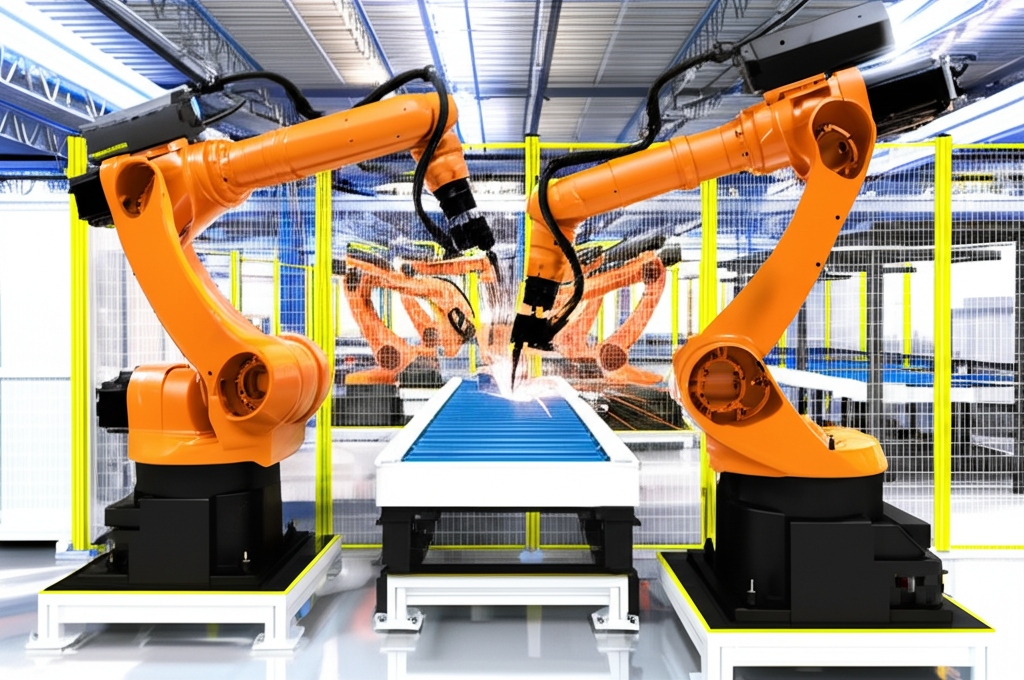

If you're seeing variations in quality despite standardized processes and training, human factors may be the variable. Robotic systems deliver consistent results regardless of time of day, fatigue levels, or environmental conditions.

Sign #3: Safety Incidents or Near-Misses Are Increasing

When operations involve high-pressure systems, confined spaces, or hazardous environments, even minor safety incidents should trigger automation considerations. Removing humans from high-risk scenarios isn't just about compliance—it's about valuing your team.

The ROI Calculation

Beyond these signs, the financial case for automation becomes compelling when:

- Labor costs exceed 40% of operational expenses

- Downtime costs are greater than the investment in automation

- Scaling operations would require significant workforce expansion

At Dezu, we've found that most industrial operations in the Philippines reach the automation tipping point earlier than they realize. The key is starting with targeted automation of specific processes rather than attempting wholesale transformation.